Instapak

Two-component-foam-system

In addition to the classic constructive packaging made of PU and PE foams, the two-component foam system closes the gap between universal filling and cushioning systems and an individually developed packaging solution. Instapak is foam packaging with almost unlimited possibilities. Available as a foam bag for direct use and as well as a complete system for your own production of foam packaging.

Automatically adapts to the packaged goods

Very low weight

Individual product protection

The form of the Instapak packaging arises directly created at the product. The two components of the polyurethane foam react together, foam up and solidifies in a very short time. The cushion forms together with the product, absorbs in a form closed way and fixes it in the outer packaging. It offers optimal product protection during the transport and within the storage. Depending on the goods, which have to be packaged, Instapak can for example also be used as edge protection.

Instapak systems

compared

The chemical reaction of the two components increases the liquid starting material to around 280 times of its volume. This is the reason, why foam cushions belong to one of the lightest packaging for filling cavities and fixing products.

To create the bags, different systems are available.

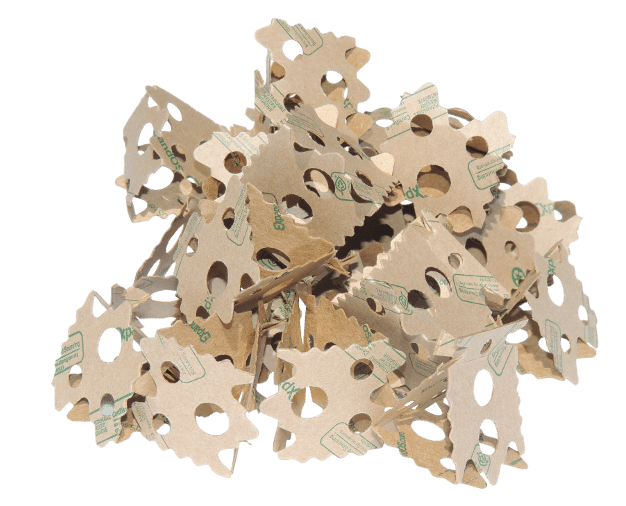

- Prefabricated bags with two chambers: Pressing firmly with the hand on a certain point opens the link between the two chambers and the material foams up. Instapak Quick RT is available in various standard sizes.

- Mechanical filling of the bags: The two substances are stored fluidly in two different tanks Through choosing the appropriate parameters at the machine, the bags are filled with the liquids. During the process these react together and foam up. There are different sizes of machines for different purposes. For foam, up to ten different sizes for hardness are available.

- Preformed cushions: In this case, the machine has integrated a tool that defines the form of the bags. This is ideal for the further processing of series of packaging and then using it as quickly as possible.

The foamed packages can simply be disposed with the residual waste and are thermally recycled. According to your wishes, with the upholstery cushions from Instapak, you can create a unique upholstery protection. Whether square, round, light or heavy – with the cushions, almost all types of products can be protected individually.

Aroused interest?

You are interested in Instapak? We are spending the time for you with pleasure to discuss your issue and respond to the given requirements. One of our packaging experts analyzes your working environment and gives you individually advice, to find the best possible packaging solution for you. Please fill out the following form or call us on 07433 904410.

Frequently asked questions

How is Instapak foam packaging used?

Place the unfolded pillow on the table in front of you. Press A and B to activate the ingredients. This starts the mixing process of the ingredients. You need about 15 repetitions for a full response. As soon as the upholstered cushion unfolds, place it in the prepared box and then insert the packaged goods. Once the foam is completely foamed, repeat this process with the second bag.

What alternative is there to Instapak?

If mainly products with identical dimensions are manufactured or shipped, an individual solution, for example a PE molded part, can possibly be used. However, if the packaged goods are often different in size, weight or shape, a real Instapak alternative can be membrane packaging.

What are the standard sizes of Instapak Quick RT?

The following bag sizes are offered as standard for Instapak Quick RT: 38×46, 46×46, 46×61, 54×68 and 64×69 cm.

{

“@context”: “https://schema.org”,

“@type”: “FAQPage”,

“mainEntity”: [{

“@type”: “Question”,

“name”: “Wie werden Instapak Schaumverpackungen angewendet?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Legen Sie das entfaltete Kissen vor sich auf den Tisch. Drücken Sie zum aktivieren der Bestandteile auf A und B. Dadurch setzen Sie den Mischvorgang der Komponenten in Gang. Für eine vollständige Reaktion benötigen Sie etwa 15 Wiederholungen. Sobald sich das Polsterkissen entfaltet, legen Sie diesen in den vorbereitenden Karton und legen Sie anschließend das Packgut ein. Sobald der Schaum vollständig aufgeschäumt ist, wiederholen Sie diesen Vorgang mit dem zweiten Beutel.”

}

},{

“@type”: “Question”,

“name”: “Welche Alternative gibt es zu Instapak?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Werden hauptsächlich Produkte mit identischen Maßen hergestellt bzw. versendet, kann möglicherweise auf eine individuelle Lösung, beispielsweise auf ein PE Formteil, zurückgegriffen werden. Sind die Packgüter jedoch oft unterschiedlich in der Größe, Gewicht oder Form, kann eine echte Instapak Alternative eine Membranverpackung sein.”

}

},{

“@type”: “Question”,

“name”: “Welche Standardgrößen von Instapak Quick RT gibt es?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Für Instapak Quick RT werden die folgenden Beutelgrößen im Standard angeboten: 38×46, 46×46, 46×61, 54×68 und 64×69 cm.”

}

}]

}