From the lightweight PP twin-wall plates, packagings are made, which can be used several times and are also suitable for the use in clean areas. The starting material is polypropylene, which is extruded as a sheet material. Due to the design of the material according to the double T-beam principle, a very high stability is obtained with a comparatively low weight.

Can be used as reusable packaging

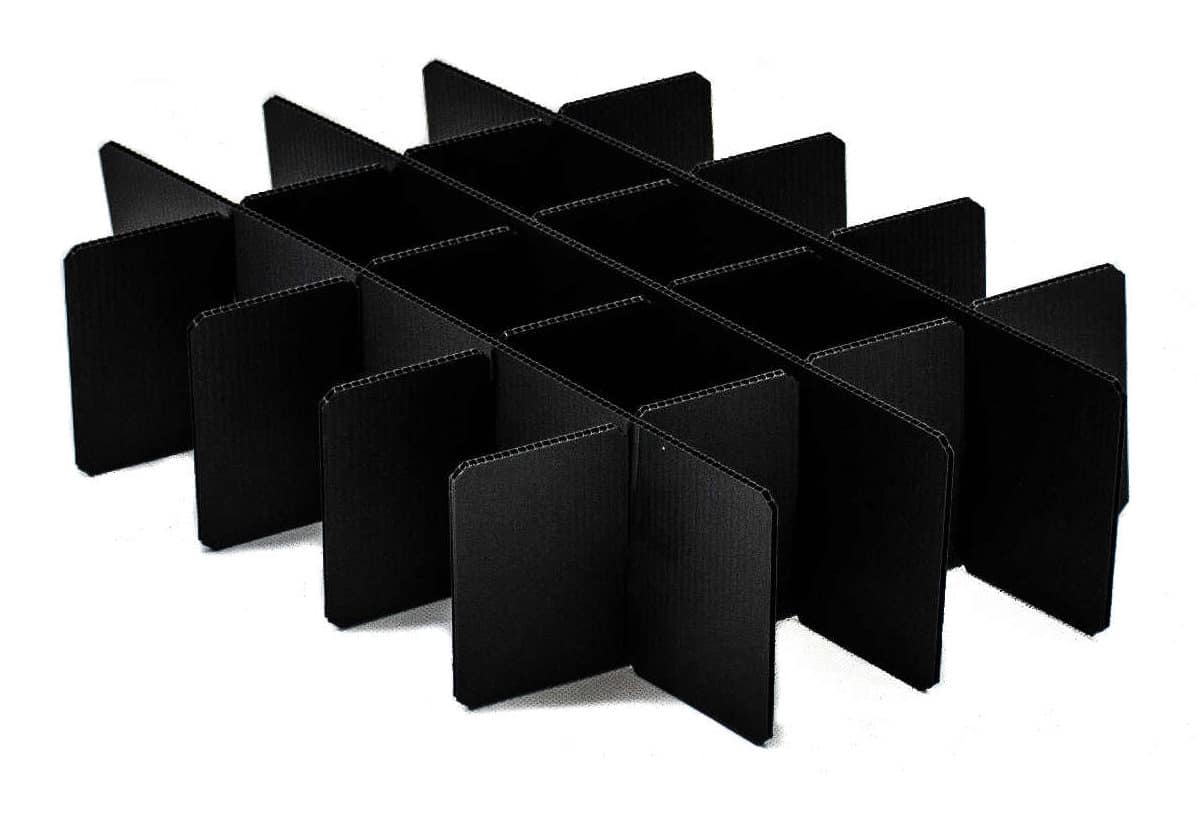

Also possible with different inserts

In principle, similar designs are possible with the twin-wall plates, which can also be made with corrugated cardboard, that is why the material is sometimes called plastic corrugated cardboard. The decisive factor for stability is not the thickness, but the weight per unit area of the material. It is manufactured in thicknesses of 2 to 20 mm with weights per unit area of 200 g / m² to 8,000 g / m². Typical designs are:

- Intermediate layers and blanks: for separating individual layers, with recesses for fixing, as a base and cover layer

- Compartments: also known as compartment distribution, bar insert, grid insert or separator, for separating and protecting individual components

- Trays and inserts: for boxes, load carriers or as a separate system

- Reusable boxes:for exchange shipping, volume-reduced return

- Linings for containers: for example standard lattice box lining

The cavity plates can easily be processed from the flat material with punching or cutting plotters. Creasing, scoring and contour lines enable a wide variety of forms. In most cases, the material is welded instead of sticking it together.

PP trilaminate plates

PP trilaminate plates

Trilaminate plates are also made of polypropylene and have a completely different structure. While multi-wall plates are extruded as one piece, these sheets are composed of three different layers. The middle layer has acell structure. As a result, these hollow-chamber structure panels have the same resistance in all directions. The typical running direction of the multi-skin plates does not appear here.

Areas of application:

- Rings for container systems

- Boxes in special formats

- Stacking trays with foam receptacles

- Intermediate layers and cuts

Trilaminate plates are mainly used for heavy parts or more robust reusable use. As with the PP cavity plates, a connection with toothed strips and receptacles made of PE foam is possible and useful.

PP solid material

Reusable packaging that is washed has special requirements. These cannot always be achieved with cavity plates and trilaminate plates. Solid PP material can be punched and processed up to a material thickness of approx. 2mm. The material has different mechanical properties than the multi-skin and structured plates, but the following products can be made from it:

- Inserted compartments (suitable for washing systems)

- Trays as inserts in boxes and KLTs

The general advantages of the base material polypropylene apply to all three versions: it is odorless, acid and solvent-resistant and suitable for use in the pharmaceutical and food industries. For the industrial sector, the material can be used with a high proportion of recycled material in order to save resources. Electrically conductive (ESD), antistatic and flame-retardant designs are possible as special designs.

More information

You can obtain more information about our twin-wall plates from one of our packaging specialists, who will assess your work environment and advise you individually.

FAQ PP Twin-Wall Sheets

What does PP mean?

PP stands for polypropylene. Polypropylene is one of the most important plastics in the packaging industry. For boxes, compartments or inlays, PP is better suited than PE, as this plastic is much harder, stronger and can withstand higher temperatures.

What can PP Twin-Wall Sheets be used for in packaging?

PP twin-wall sheets are light, stable and versatile. In the packaging industry, twin-wall sheets can be used as storage and transport protection. The following products can be manufactured with twin-wall sheets:

- Intermediate layers

- Compartments (plugged and unmated)

- Lattice box linings

- Lid for KLT

- Trays

- Stamped parts

- Product carrier

- Stand-up

- Boxes

- Boxes

- edge protection

- ESD packaging

Which grammages or qualities are possible?

Twin-wall sheets can be manufactured with a quality of 2.00 to 10.00 mm or between 250 g / m² and 2000 g / m², depending on requirements and product type.

What colors are possible?

In the packaging industry, twin-wall sheets are manufactured in black or anthracite. Other colors such as yellow, red, green, blue, natural and white are also possible on request.

Zwischenlagen Gefache (gesteckt und ungesteckt) Gitterboxauskleidungen Deckel für KLT Trays Stanzteile Warenträger Aufsteller Kisten Boxen Kantenschutz ESD Verpackung" } },{ "@type": "Question", "name": "Welche Grammaturen bzw. Qualitäten sind möglich?", "acceptedAnswer": { "@type": "Answer", "text": "Hohlkammerplatten können je nach Bedarf und Produktart mit einer Qualität von 2,00 bis 10,00 mm bzw. zwischen 250 g/m² und 2000 g/m² hergestellt werden." } },{ "@type": "Question", "name": "Welche Farben sind möglich?", "acceptedAnswer": { "@type": "Answer", "text": "In der Verpackungsmittelbranche werden Hohlkammerplatten in schwarz bzw. anthrazit gefertigt. Auf Anfrage sind aber auch andere Farben wie Gelb, Rot, Grün, Blau, Natur und Weiß möglich." } }] }